At Lanson, we go beyond being a service provider; we are your strategic partner in PCB manufacturing. Our advanced facilities, experienced team, and commitment to excellence set us apart in the industry. When you choose us for your turnkey PCB needs, you benefit from a seamless, efficient, cost-effective solution that meets the highest quality standards.

- Welcome to Lanson Technology!

Service Introduction

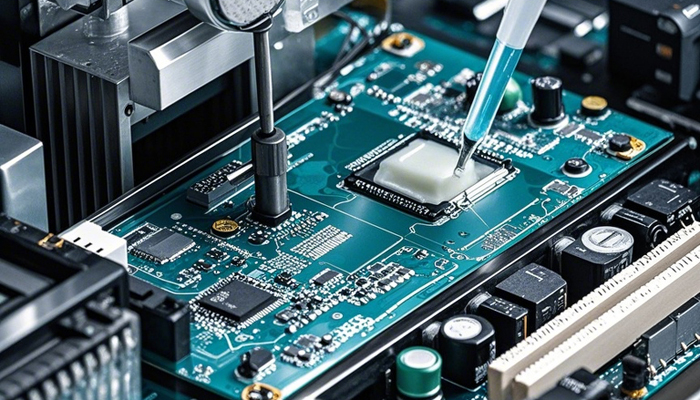

High quality solder paste

LANSON always requires to purchase high-quality solder paste for production, such as Senju alpha, loctite and other well-known brands, which can also be produced with uneven surface.

Reliable electronic components

Massive brands, massive spot inventory, one-stop order distribution service, one-stop original genuine suppliers.

Service Area

Service Process

Customer Consultation

Formulate Scheme

Sign Contract

Customized Processing

Loading Delivery

After Sales

12 years of focus on PCB manufacturing, high-quality service

Email Us: sales@lansonpcb.com

Frequently Asked Question

-

Why Choose Lanson for PCB Manufacturing?

-

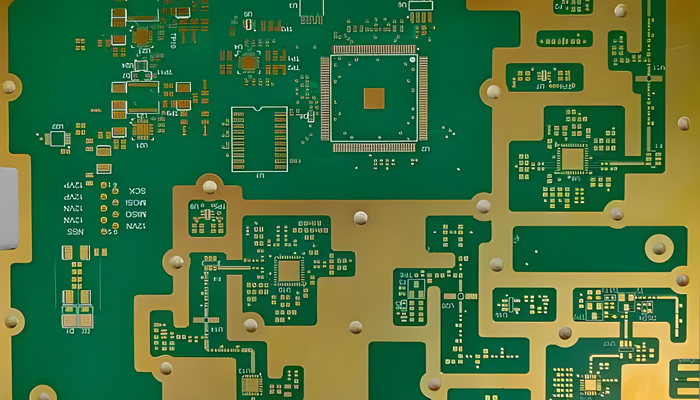

Why are there solder holes in SMT chip processing?

For core devices such as QFN, the packaging is unique and the process is difficult. The side of the welding end is exposed and there is no weldable coating. Generally speaking, the weldability of the left and right sides of the welding end is very poor in SMT processing, which is prone to poor wetting, bridging and voids. In this case, it is mainly because the thin solder paste is more likely to form a larger cavity. The main reason is that the thickness gap of the weld is too small, which makes it more difficult for the volatiles of the welding machine to be discharged through this "channel", resulting in the problem of "cavity".