- Welcome to Lanson Technology!

The Role of Metal Core PCBs in High-Performance Electronics: A Manufacturer’s Guide

As technology continues to evolve, the demand for high-performance electronics has surged, prompting the need for advanced manufacturing solutions. Metal Core PCBs (Printed Circuit Boards) have emerged as a key player in meeting these demands, providing a robust foundation for electronic devices that require enhanced thermal management and durability.

As a leading Metal Core PCB manufacturer, Lanson PCB is at the forefront of this technological frontier, offering insights into the significance and applications of Metal Core Circuit Boards.

Understanding Metal Core PCBs: A Brief Overview

Metal Core PCBs, often referred to as MCPCBs, distinguish themselves from traditional PCBs by having a metal core, typically composed of aluminium or copper. This metal core acts as an efficient heat sink, dissipating heat generated by electronic components and ensuring optimal performance. The dielectric layer, which insulates the circuit, is crucial in maintaining electrical isolation.

Benefits of Metal Core PCBs for High-Performance Electronics

- Superior Thermal Conductivity: Metal Core PCBs excel in thermal management, efficiently dissipating heat generated by power components. This results in enhanced reliability and longevity of electronic devices, making them ideal for automotive, aerospace, and telecommunications applications.

- Enhanced Mechanical Strength: The metal core provides robust structural support, contributing to the overall durability of the PCB. This is especially valuable in applications where the board may be subjected to vibrations, mechanical stress, or challenging environmental conditions.

- Improved Power Density: High-power electronic devices benefit from Metal Core PCBs because they can accommodate increased power densities without compromising performance. This makes them preferred for power converters, LED lighting, and motor drives.

Applications Across Industries: Where Metal Core PCBs Shine

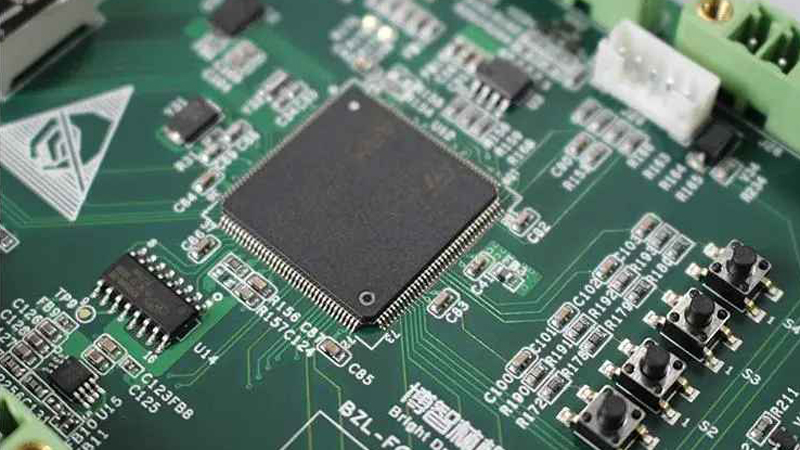

- Automotive Electronics: Metal Core PCBs are pivotal in automotive electronics, where reliability and thermal management are paramount. They are used in engine control units, LED lighting systems, and power electronics, contributing to the efficiency and safety of modern vehicles.

- LED Lighting: The LED lighting industry leverages Metal Core PCBs to address the thermal challenges associated with high-brightness LEDs. This ensures consistent performance and longevity, making Metal Core PCBs the go-to solution for high-quality LED applications.

- Power Electronics: Metal Core PCBs are instrumental in devices such as inverters, power converters, and motor drives in power electronics. The enhanced thermal conductivity and mechanical strength make them indispensable for efficient power management applications.

Lanson PCB: Your Trusted Metal Core PCB Manufacturer

As a distinguished Metal Core PCB manufacturer, Lanson PCB is committed to delivering cutting-edge solutions that meet the evolving requirements of the electronics industry. Our up-to-date manufacturing facilities and a team of experienced professionals ensure the production of high-quality Metal Core Circuit Boards tailored to your specific requirements.

Advancing Electronics with Metal Core PCBs!

Metal Core PCBs symbolize innovation and dependability in the ever-changing world of high-performance electronics. As technology continues to promote boundaries, the role of Metal Core Circuit Boards will only become more prominent. Lanson PCB remains dedicated to driving this progress, providing the foundation for electronic devices that power the future!