- Welcome to Lanson Technology!

Exploring Advanced Techniques: Next-Level PCB SMT Assembly Solutions

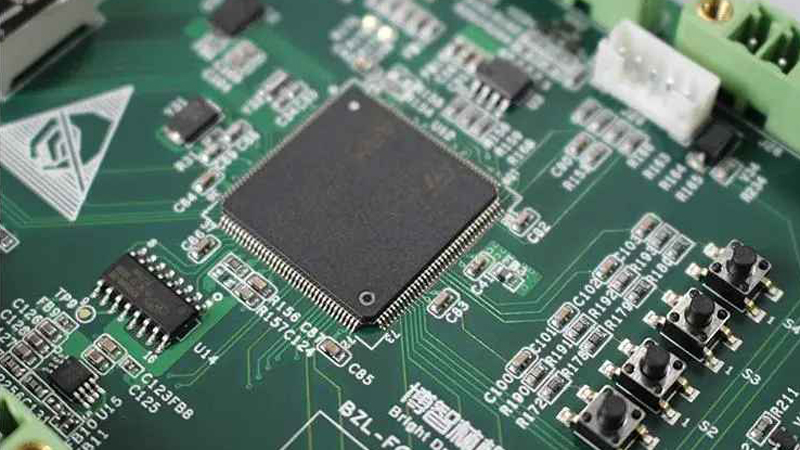

When it comes to Printed Circuit Board (PCB) manufacturing, the intricate process of Surface Mount Technology (SMT) Assembly plays a pivotal role in determining the efficiency and reliability of electronic devices. At Lanson PCB, we take pride in our commitment to delivering cutting-edge solutions in PCB SMT Assembly, pushing the boundaries of technology to meet the evolving demands of the electronics industry.

Solution The Intricacies of PCB SMT Assembly

- Precision at its Core

At Lanson PCB, we understand that precision is non-negotiable in PCB SMT Assembly. Our advanced techniques ensure that every component is placed with utmost accuracy, minimizing the risk of errors and optimizing the final product's functionality. This precision is not just a goal for us but a standard that defines our commitment to quality.

- State-of-the-Art Equipment

The backbone of any successful SMT Assembly process lies in the technology and equipment used. Our state-of-the-art facilities boast cutting-edge machinery that is efficient and ensures a streamlined and flawless assembly process. From automated pick-and-place machines to high-precision soldering equipment, we invest in the newest technology to guarantee the highest standards in SMT Assembly.

SMT PCB Board: Redefining Connectivity

- Miniaturization for Efficiency

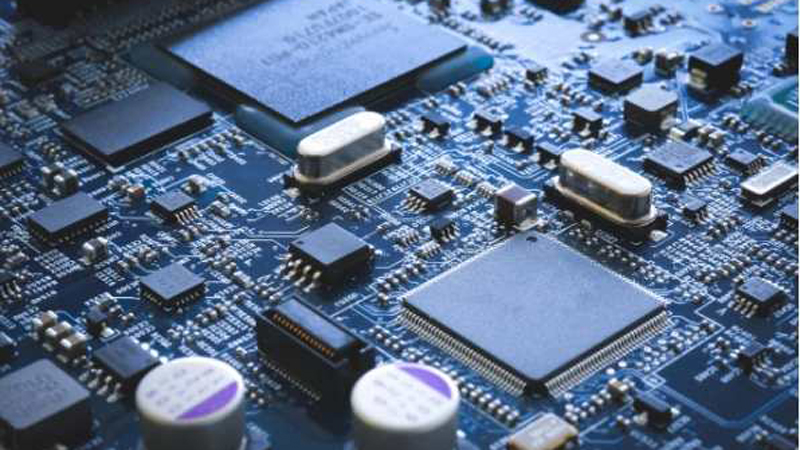

The demand for smaller and more efficient PCBs is rising in a world where electronic devices are becoming increasingly compact. Our SMT PCB Boards are designed with miniaturization in mind, ensuring that components are placed with minimal spacing while maintaining optimal functionality. This reduces the overall footprint of the PCB and enhances the efficiency of the electronic device.

- High-Density Interconnects

Our SMT PCB Boards incorporate high-density interconnects to keep pace with the evolving connectivity needs. This allows for more connections within a confined space, facilitating the seamless flow of data and signals. The result is a PCB that meets the current connectivity standards and future-proofs the device for upcoming technological advancements.

Innovations in PCB SMT Assembly

- 3D Printing for Prototyping

In our pursuit of innovation, we leverage 3D printing technology for prototyping in PCB SMT Assembly. This enables us to quickly iterate and test different designs, significantly reducing time-to-market for our clients. Visualizing and assessing prototypes in a tangible form allows us to make smart decisions, ensuring the final product meets the leading quality and functionality standards.

- Smart Soldering Techniques

Soldering is a critical aspect of SMT Assembly, and we take it to the next level with smart soldering techniques. Our automated soldering processes are optimized for efficiency and consistency, ensuring that each joint is secure and reliable. Smart soldering enhances the overall quality of the assembly and contributes to the longevity of the electronic device.

Quality Assurance: Our Pledge

- Rigorous Testing Protocols

Our commitment to delivering superiority extends to our rigorous testing protocols. Every PCB undergoing SMT Assembly at Lanson PCB undergoes thorough testing to identify potential issues. From functional testing to environmental stress testing, we leave no stone direct to ensure that our clients receive PCBs that meet the supreme standards of quality and reliability.

- Continuous Improvement

Quality assurance is not a one-time effort but a continuing journey. At Lanson PCB, we believe in the philosophy of continuous improvement. We constantly evaluate and enhance our processes, incorporating feedback and staying abreast of industry trends to provide our clients with PCBs that are at the forefront of technological advancements.

The Lanson PCB Advantage

- Customer-Centric Approach

What sets Lanson PCB apart is our unwavering commitment to our clients. We adopt a customer-centric approach, understanding their unique requirements and tailoring our solutions to meet and exceed expectations. Our team of experts works carefully with clients throughout the entire SMT Assembly process, ensuring transparency, collaboration, and a final product that aligns seamlessly with their vision.

Environmental Responsibility

In our pursuit of excellence, we don't lose sight of our responsibility towards the environment. Lanson PCB is dedicated to sustainable practices in PCB manufacturing. We adhere to eco-friendly processes and materials, minimizing waste and energy consumption. Our commitment to environmental responsibility is a testament to our holistic approach to business.

Empower Your Electronics With Lanson PCB's Precision Expertise

In the ever-evolving electronics landscape, Lanson PCB is a beacon of innovation and reliability in PCB SMT Assembly. Our advanced techniques, state-of-the-art equipment, and unwavering commitment to quality make us the preferred partner for clients seeking next-level solutions in PCB manufacturing. As we continue to push the boundaries of technology, we invite you to join us on this journey toward excellence in SMT Assembly. Your vision, our expertise – together, we shape the future of electronics!